Andrew Bass

August 12, 2024

Batch chemical manufacturing comes with quite a few challenges that make it distinct from discrete unit production (eg: cars, clothing, electronics). These complexities make accurate production scheduling and forecasting difficult, leading to underutilization of your equipment or late deliveries to your customers. Let’s dig into some of the key causes of this variability.

Conditional Process Steps

Anyone who has made cookies knows that the bake time from the recipe is at best a guideline. You are going to need to wait for a condition to be true before you pull them out: you see them golden brown and delicious.

Chemicals are the same: certain steps require a condition to be true before moving on, such as boiling off water until the volume is reduced by a certain amount, or until the viscosity reaches a designated level. This requires periodic work in progress (WIP) sampling and adds to variability of the process. External conditions such as the weather, experience of the operator, and any minor mis-weighs of raw materials can affect the timing of each step in the manufacturing of the batch.

Quality Testing and Approval

In large batches of specialty chemicals, the quality lab often is required to sign off that the batch meets the product specification before packaging can begin. This ensures that the batch is still in the mixer (or other vessel) so that any needed adjustments can be made quickly. However, this also means that the equipment is occupied until the lab signs off, and delays in testing and approval affect the end-to-end cycle time of the product.

In one extreme case, we spoke with a plant that sends a sample of each batch to their end customer by mail to get final approval of the color. That adds several extra days of delay, leaving them both at the whim of the postal service and their customer’s timely response. These potential delays combine to increase the overall variability of their batches.

Multi-Sourced Ingredients

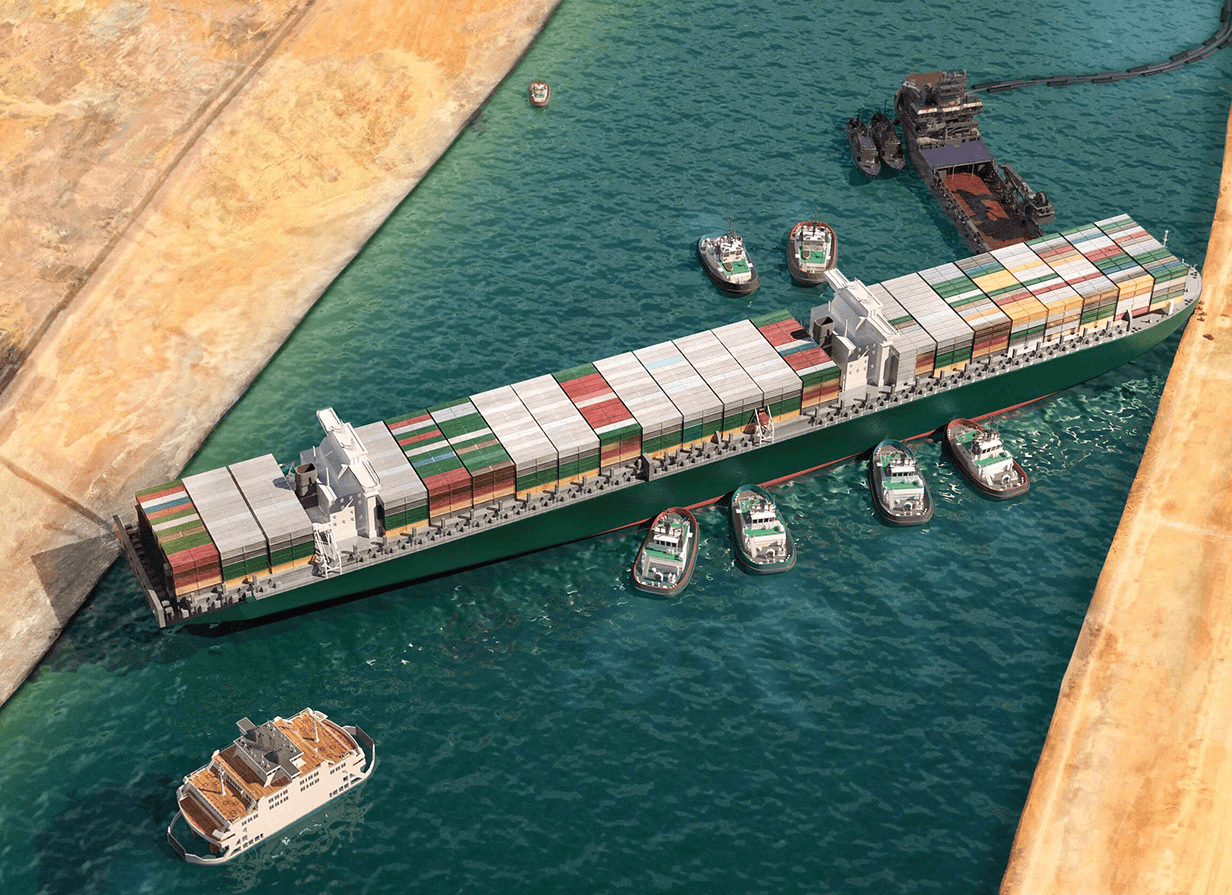

In the wake of COVID, global supply chains have become increasingly volatile. In efforts to increase their resilience against delays, many companies are moving to source key materials from multiple suppliers. However multiple vendors means an opportunity to introduce additional variation in the overall production process. Even two different materials that are both technically satisfying their spec can behave differently at scale, adding variability to production.

Equipment Differences

Anyone who has baked cookies also knows that no two ovens will behave exactly the same way. The same is true for industrial mixers, boilers, and reactors. Equipment size, age, and cleanliness all play roles in the manufacturing process. We’ve heard from a plant that found that a certain boiler on the far end of their plant had a lower gas pressure, so would heat much slower than the others. This caused the cycle time of some batches to increase by as much as 20%!

How Variability affects Production Planning

To ship orders on time for customers, production schedulers plan out which batches to assign to each piece of equipment and when each order will be made. But if a batch unexpectedly runs 12 hours long, this can throw off the entire production plan for the rest of the week, delaying critical shipments to high-value customers. A common way to combat this is to plan for additional buffer time to accommodate unexpected delays.

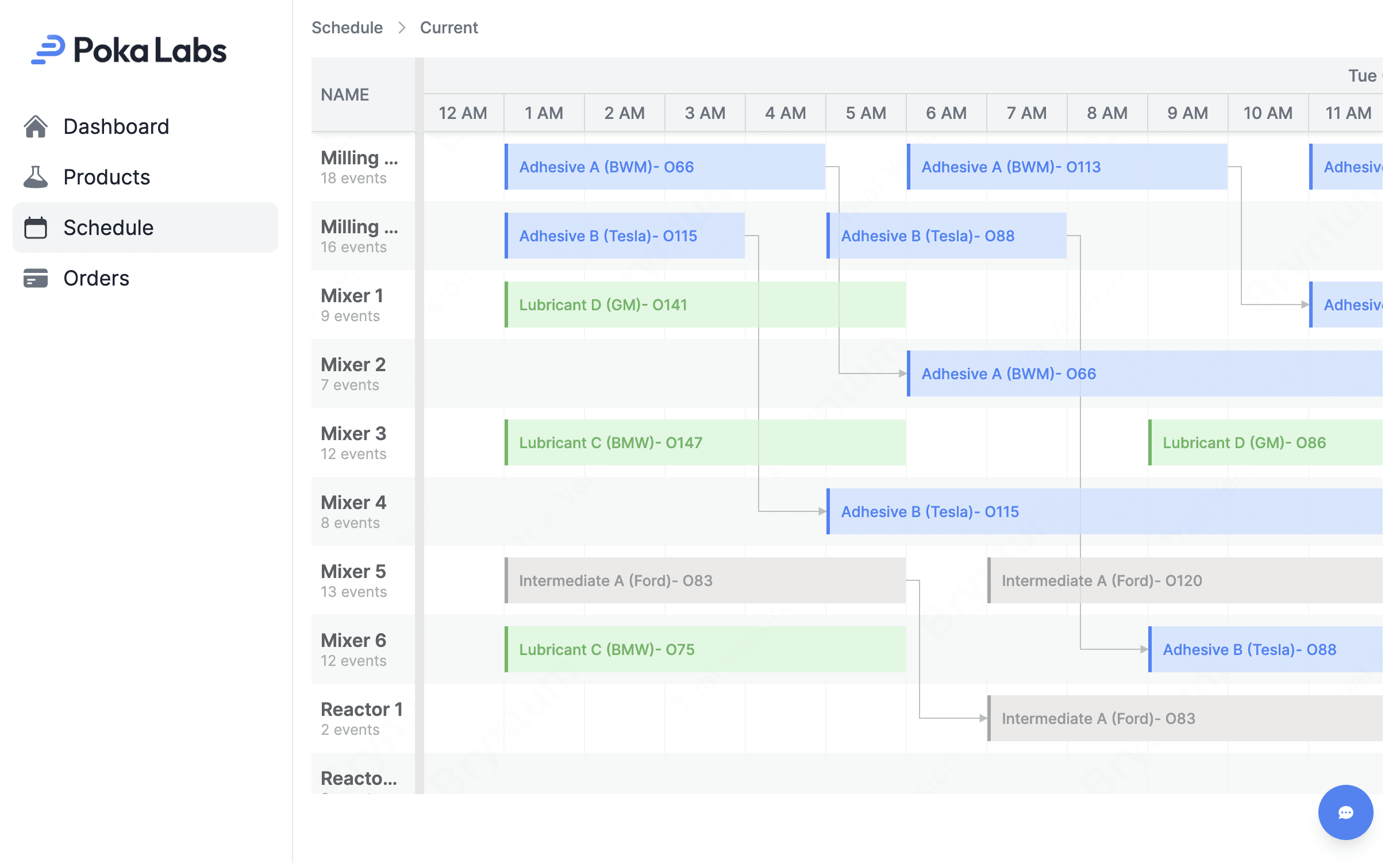

However, this decreases your equipment utilization, which means you aren’t getting the most out of your company’s expensive capital investments. Instead, your plant needs to build this variability into its production schedule, considering things like equipment assignment when estimating the cycle time of each batch. With most scheduling today happening on spreadsheets and whiteboards, this level of complexity becomes extremely challenging at scale.

Poka Labs is building modern scheduling software to help chemical manufacturers take control of the variability in their production. Reach out to us at founders@pokalabs.com to see our platform in action. We’ll send you a box of cookies too.